In the competitive world of garment manufacturing, precision in cutting is the cornerstone of quality. Auschalink Clothing Factory, a rising star in the industry, has garnered attention for its innovative approach to fabric cutting and production efficiency. But what sets this factory apart? Let’s delve into the technological prowess and strategic advantages that make Auschalink a leader in its field.

1. Cutting-Edge Technology and Process Optimization

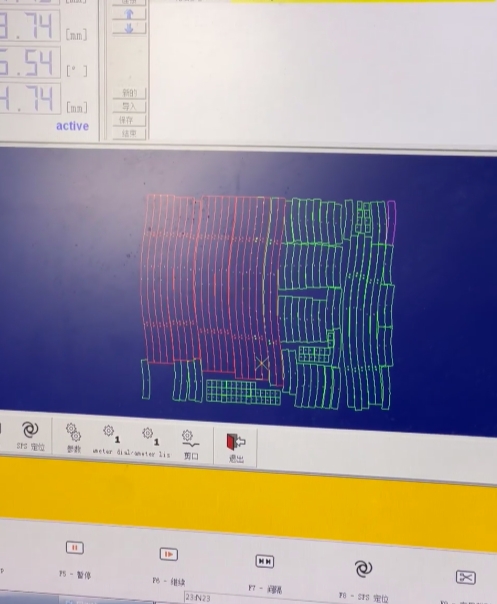

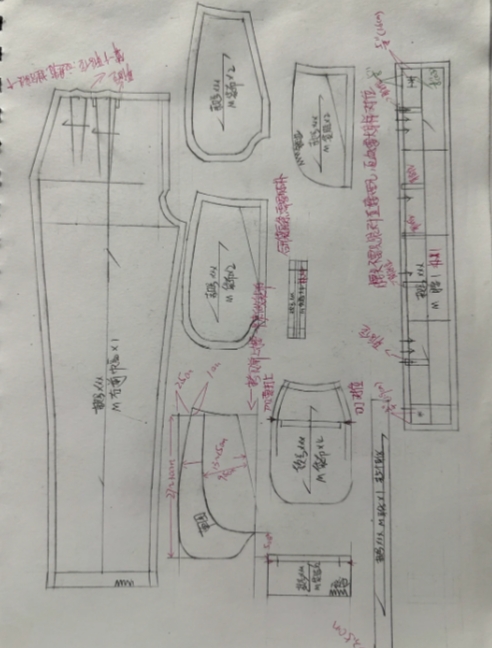

Auschalink integrates advanced ERP systems to streamline workflows, from order management to production planning. By automating data entry and reducing manual errors, the factory ensures seamless coordination between design, material procurement, and processes. Their state-of-the-art cutting machines, guided by AI-driven algorithms, achieve millimeter-level accuracy, minimizing fabric waste and maximizing yield—a critical factor in sustainable manufacturing.

2. Uncompromising Quality Control

At Auschalink, every cutting bed stage undergoes rigorous scrutiny. Inspired by the "artisan spirit" seen in high-end animation costume factories, workers meticulously inspect fabrics for flaws before cutting, ensuring only premium materials proceed to production. Double-stitched seams and reinforced stress points—techniques borrowed from top overalls manufacturers—guarantee durability even under heavy use.

3. Sustainability Meets Efficiency

Aligning with global trends, Auschalink adopts eco-friendly practices. Like Türkiye's textile leaders, the factory invests in water-saving technologies and renewable energy to reduce its environmental footprint. Combined with bulk purchasing of sustainable fabrics, this approach not only lowers costs but also appeals to environmentally conscious brands seeking ethical partners.

4. Agile Production for Global Demands

Strategically located near major shipping hubs, Auschalink mirrors Türkiye's geographical advantage, offering faster delivery to European and North American markets. Their flexible production lines accommodate both mass orders and small-batch customization requests, a feature increasingly demanded by fast-fashion and niche brands alike.

5. Collaborative Innovation

Auschalink fosters close partnerships with clients, echoing the "Customer first" philosophy of top-tier processing plant. Designers collaborate directly with the factory’s R&D team to translate creative concepts into wearable art, whether replicating iconic cartoon character costumes or engineering high-performance workwear.

Client Testimonial:

"Working with Auschalink transformed our supply chain," says Emma Larson, CEO of a sustainable apparel brand. "Their precision cutting reduced material waste by 20%, and their transparency in production timelines is unmatched."

Conclusion: The Future of Garment Manufacturing?

Auschalink’s blend of technology, quality, and sustainability positions it as a model for modern garment factory. As the industry shifts toward ethical and efficient practices, this factory’s cutting bedexpertise and adaptive strategies may well set a new global standard.

Post time: Mar-17-2025